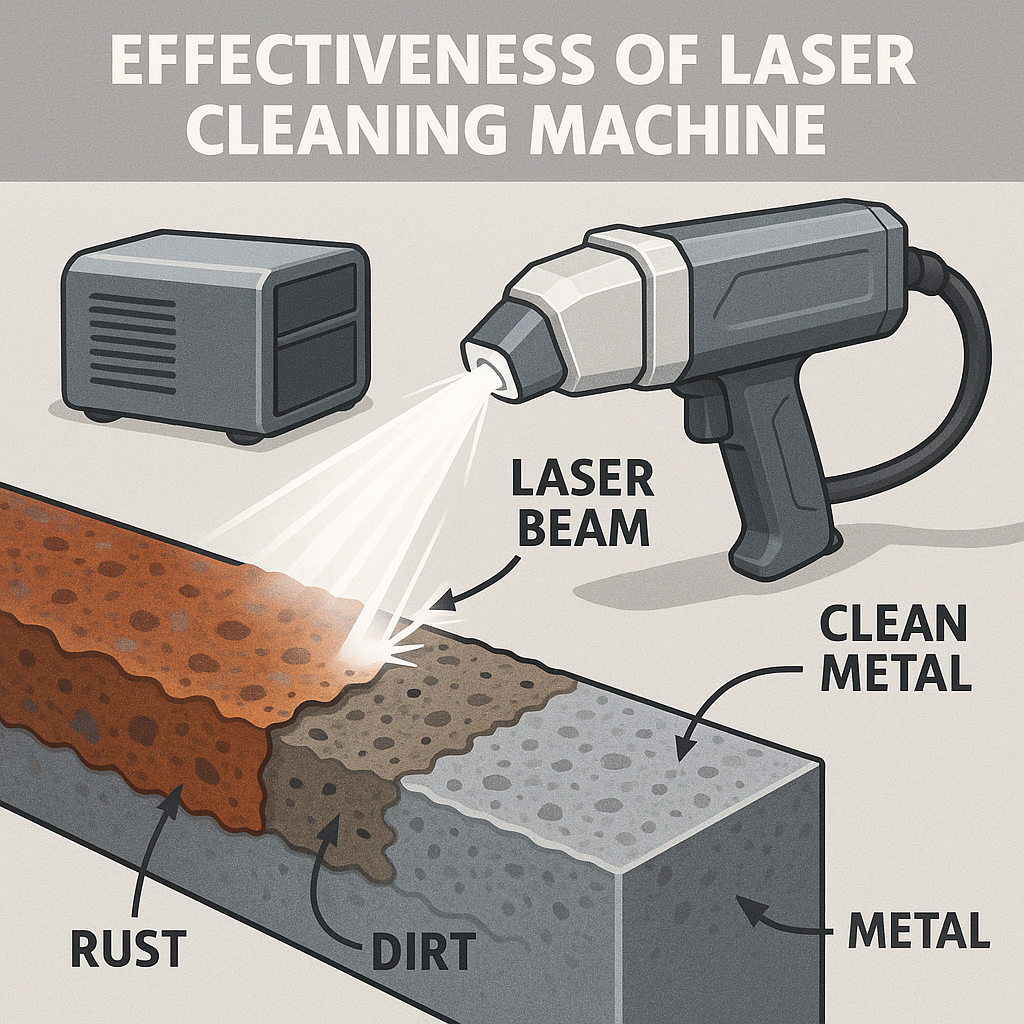

This pulsed, air-cooled laser cleaning machine utilizes a high-frequency pulsed laser source (100-500W optional) combined with an air-cooling system, avoiding the complexities of water cooling. It offers high cleaning efficiency and is suitable for removing oil, rust, and oxide layers.

Product Overview:

Employing an air-cooling system, it avoids the complex maintenance of traditional water-cooled equipment, making it suitable for portable and on-site operation. The laser wavelength is 1064nm, with a pulse energy up to 1.5mJ, supporting fine cleaning without damaging the substrate. According to a 2025 market report, the global pulsed laser cleaning machine market is projected to reach $642 million.This pulsed air-cooled laser cleaning machine achieves 2-3 times the cleaning efficiency of traditional methods, and is suitable for small and medium-sized enterprises to large industrial settings.

Key Features

1. Pulsed Laser Technology: High-frequency pulses (20-2000kHz) ensure precise control, suitable for cleaning heat-sensitive materials and avoiding heat-affected zones. Pulse length is selectable from 10-350ns, supporting multi-mode operation (pulsed & continuous).

2. Air Cooling System: Built-in high-efficiency air-cooling module eliminates the need for an external water source, reducing operating costs by 30-40%. The machine weighs only about 25kg, making it easy to carry.

3. Intelligent Control Software: Touchscreen interface, supports remote control via APP, and one-click parameter adjustment. Integrated fume extraction system, compliant with CE environmental standards.

4. High Durability: Laser source lifespan up to 100,000 hours, free maintenance, suitable for continuous industrial use.

5. Multifunctional Scanning Head: Cleaning width 100-200mm, supports automatic scanning, adaptable to complex surfaces.

6. Safety Design: Laser safety level 4, equipped with a protective cover and emergency stop button to protect the operator.

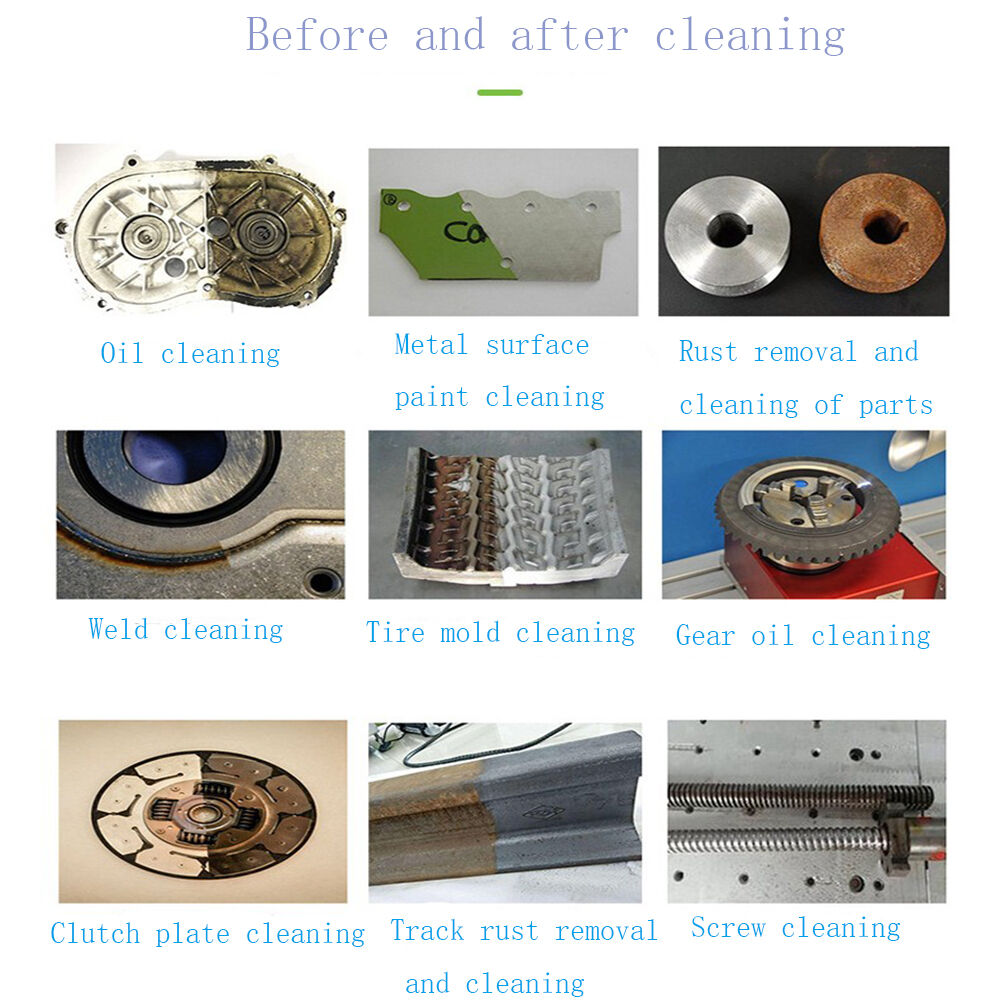

Application Areas:

1. Industrial Rust Removal and Paint Stripping: Used for removing rust, oil, and coatings from metal surfaces, suitable for automotive parts and marine maintenance.

2. Mold and Electronics Cleaning: Precision cleaning of molds, circuit boards, and electronic components without damage, extending product lifespan.

3. Aerospace and Medical: Maintenance of aerospace components and sterilization of medical devices, supporting contactless sterilization.

4. Heritage and Construction: Heritage restoration and building surface cleaning, environmentally friendly with no secondary pollution.

5. Others: Wood, stone, and ceramic treatment, extending to the home furnishing and petrochemical industries.

According to market analysis, the application share in 2025 is: automotive industry 20%, electronics industry 15%, and marine industry 10%, with the market expected to grow to $1.034 billion by 2032.

Real-world Case Studies:

1. Automotive Manufacturing Case: A Vietnamese auto parts factory introduced a 200W pulsed air-cooled laser cleaning machine for rust removal and coating removal. Results: Cleaning efficiency increased by 50%, surface quality improved, no chemical solvents required, and annual cost savings of 30%. Previously used abrasive grinding methods, which damaged the substrate, have now been completely replaced.

2. Aviation Maintenance Case: American Airlines uses a 300W model to clean aircraft engine parts. The case shows: Cleaning time was reduced from hours to minutes, thermal impact was minimized, and FAA standards were met. Market reports indicate that such applications are driving a CAGR of 12%.

3. Artifact Restoration Case: European museums use a 100W portable device to restore antique metal artifacts. Results: Oxide layers were removed without damaging the texture, project efficiency increased by 40%, and significant environmental advantages were observed.

4. Electronics Industry Case: A South Korean electronics factory applied this technology to circuit board cleaning, reducing defect rates by 20% and supporting precision micromachining.

If you are interested in this pulsed air-cooled laser cleaning machine, please contact us for a quote or to schedule a demonstration.